The Flow Expert

Improve the material flow

Flow seminar

In our EWAB flow seminar you will learn how a proper workpiece flow in production will help you to achieve operational excellence.

You can build a know-how for solutions that creates maximum throughput, and learn about the shortest lead time with less work-in-process in your manufacturing line.

✅ Production flow principles

✅ Usage of a buffer

✅ Bottleneck protection

✅ Kanban, Lean and ConWIP theories

Flow analyze

Many companies struggle to achieve their desired production output. Don’t worry – you’re not alone, and we can help with a flow analysis of your production line.

To optimize the flow, every part of the transport process must function correctly—this is crucial for your throughput. A material flow analysis can include:

✅ How does each operation work?

✅ Where are the bottlenecks?

✅ Are the cycle times accurate for each operation?

✅ Where are buffers needed?

After a full day of observation and analysis at your facility, you will receive a report with conclusions and concrete recommendations to optimize your production flow. We have done this many times and can assure you satisfaction with the analysis and report.

Connected Services

Connect your EWAB system and embrace your digitalisation journey.

Connected systems is a strategic move that gives you deeper insights into the throughput of parts within your production process. Nevertheless, this data revolution gives you more than just streamlining operations.

✅ Visualize

✅ Reporting for production improvement

✅ Predictive Maintenance

You can uncover hidden constraints and enable predictive maintenance, saving both time and costs for your company.

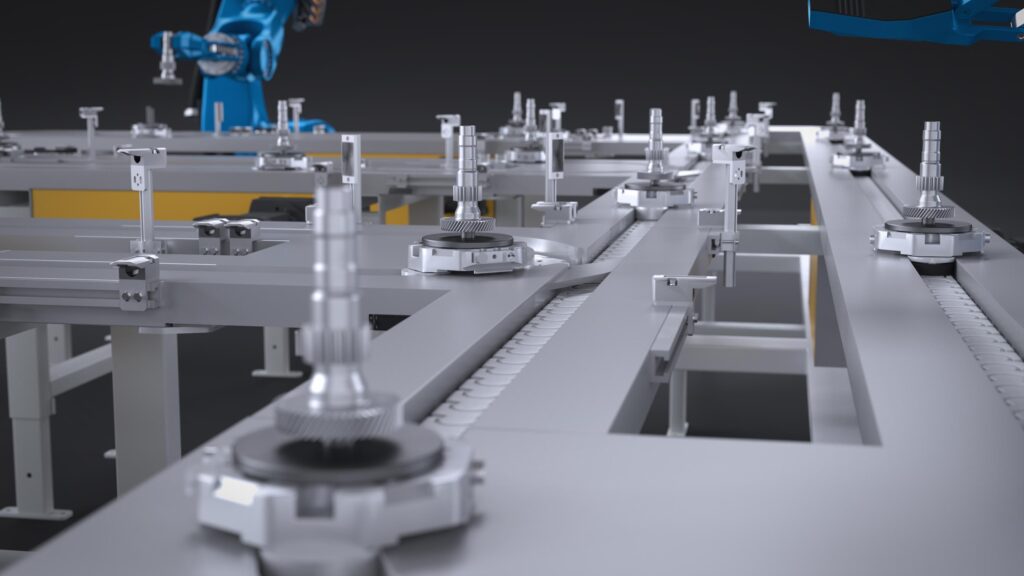

Workpiece Carrier Flow Solutions.

It´s not just a conveyor transporting your parts from one operation to another.

It´s a lot more sophisticated and science based than you may realize.

Within our System Solutions there is 50 years of material flow knowledge, decades of dedication to innovation and improvement for manufacturing production.

Over the years, our understanding for material flow have only grown.

Today, our Workpiece Flow Solutions incorporate the principals of

Theories of Constraint, CONWIP and Lean manufacturing.

They are based on simple rules, and our production lines are Drum-Buffer-Rope enabled. We believe that the ultimate production result is a hybrid combination of Kanban, ConWIP and Theory of Constrains.

The result of this is what we call the SmartFlow Effect.

The EWAB systems are synchronized to protect the manufacturing resources from starvation. What we achieve is the right workpiece at the right place at the right time, every time.