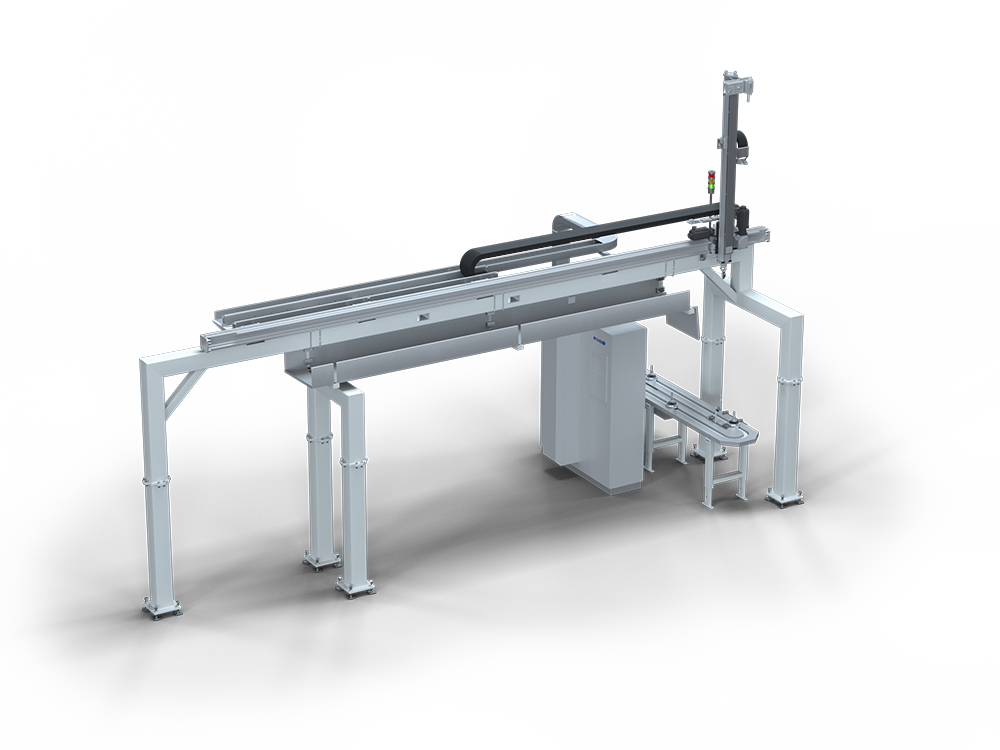

Gantry, portals and peripherals

Optimize your machine loading

In industrial manufacturing, there are numerous methods to efficiently load machines.

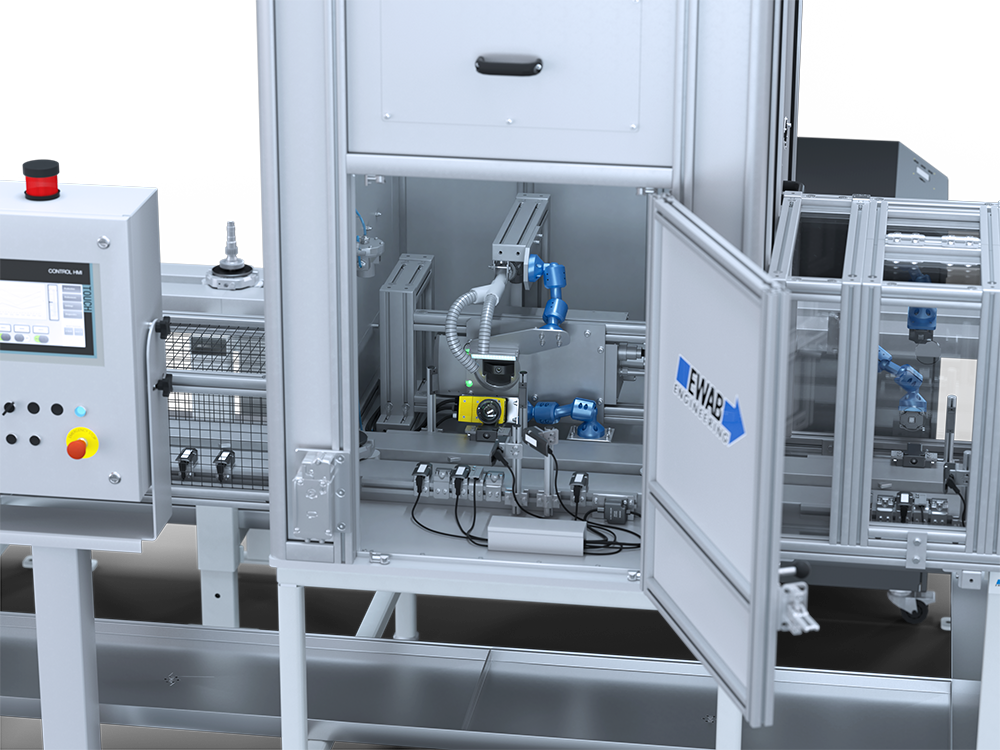

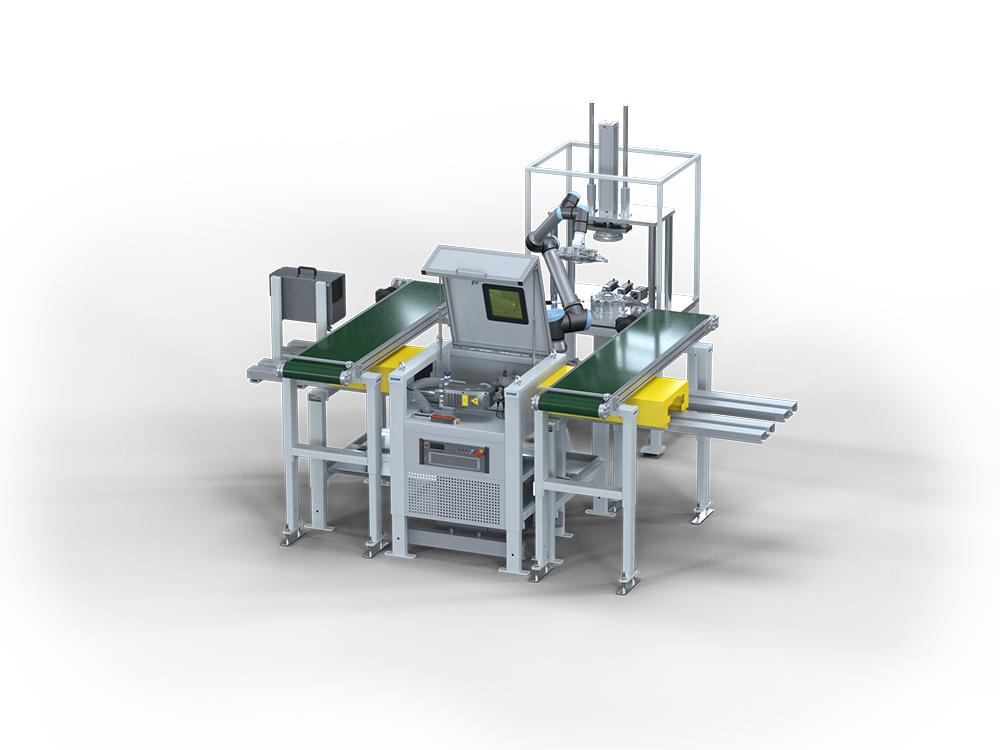

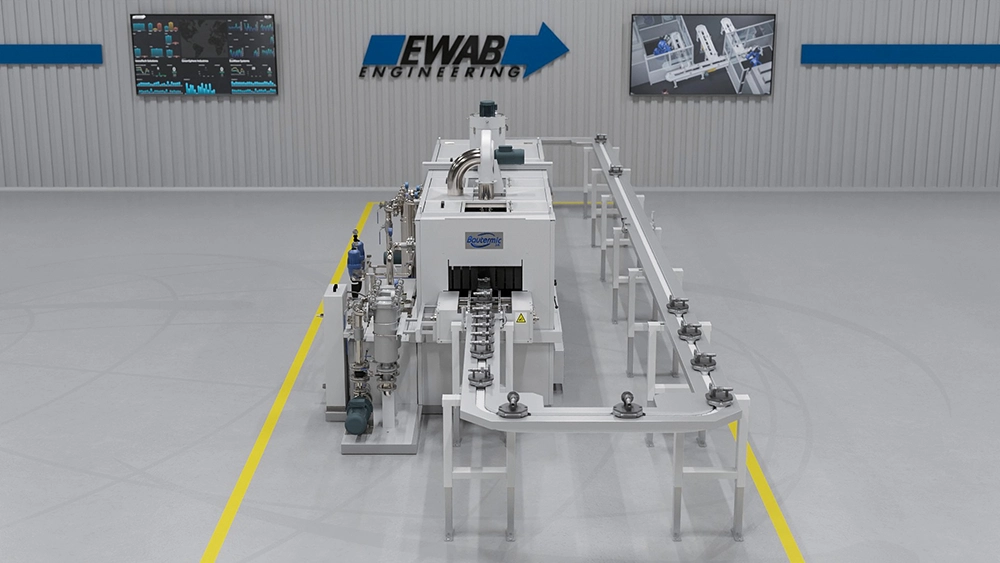

The EWAB systems are designed to integrate effortlessly with a variety of automation equipment such as gantries, robots, cobots, and conveyor peripherals. Therefore, this hallmark of standardization is crucial for ensuring operational efficiency, adaptability, and streamlined processes in diverse manufacturing environments.

Beyond our expertise in material flow and conveyor systems, we also specialize in a wide range of loading and unloading solutions. We offer diverse machine loading options, including robotic loading, gantry systems, and pick-and-place solutions. Servo-Electric gantries, offering high-speed and accuracy in material handling.

Partnering with you, we create innovative, customized loading solutions that meet your specific requirements.

Conveyor automation peripherals

At first, we have established ourselves as a reliable supplier for major Original Equipment Manufacturers (OEMs) and Tier 1 & 2 suppliers in the automotive industry, reflecting the trust and confidence placed in the quality and reliability of our systems.

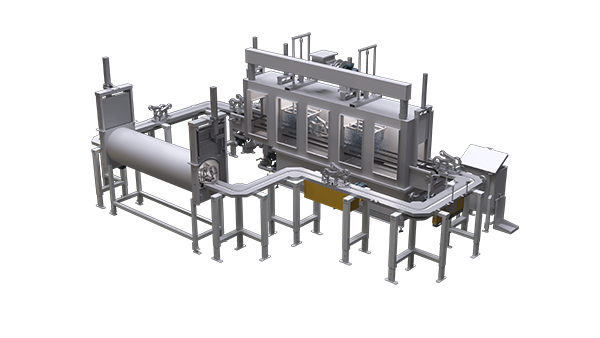

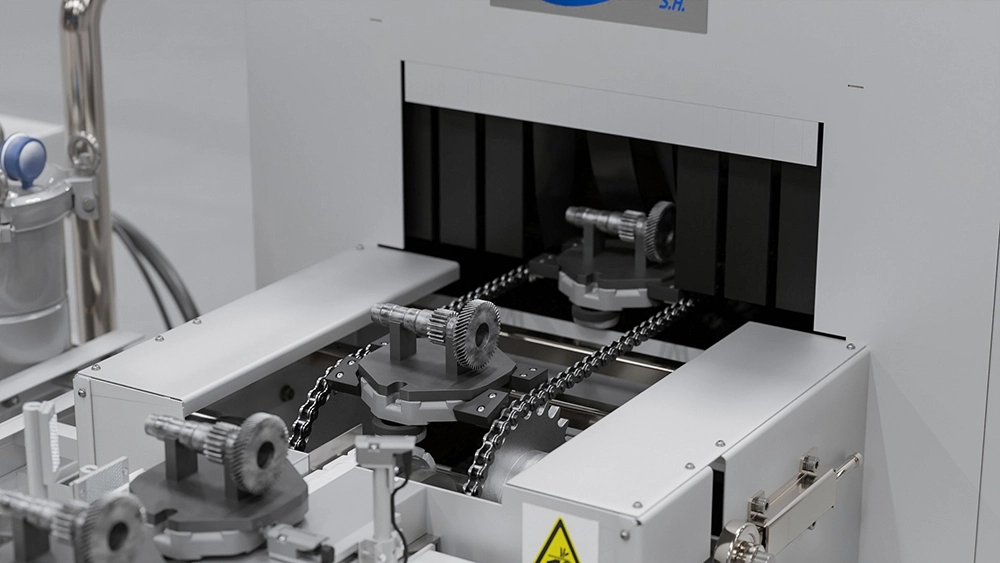

Use an EWAB conveyor when you need to wash your parts. Here in combination with a washing machine from a supplier in Sweden.

- Laser Marking for high-quality, permanent labeling of parts.

- Advanced Labeling systems for accurate identification and tracking.

- Cleaning and Washing units for maintaining part cleanliness.

- Solutions for Part Orientation to ensure correct positioning.

- Cooling Tunnel Solutions for temperature regulation in manufacturing processes.

- Testing & Analyzing equipment for ensuring product integrity.

- Quality Check Stations for meticulous inspection of finished products.

- SPC (Statistical Process Control) for maintaining production quality.

In most of our automation projects, the need for automated stations and machines are high. Therefore, we have built the knowledge to support your investment with washing and cleaning of the workpieces, quality check control and SPC-stations, part orientation, as well as labelling, laser marking and traceability of your manufactured products.

Made for high-end demands

In today’s dynamic and ever-evolving automotive sector, where precision, efficiency, and flexibility are paramount, our systems are ideally suited to meet these pressing demands.

We offer comprehensive support, encompassing not just the supply of equipment but also its integration into your operational framework. This includes both the physical installation and software integration.