Cobots integration

Add Cobots to your production line

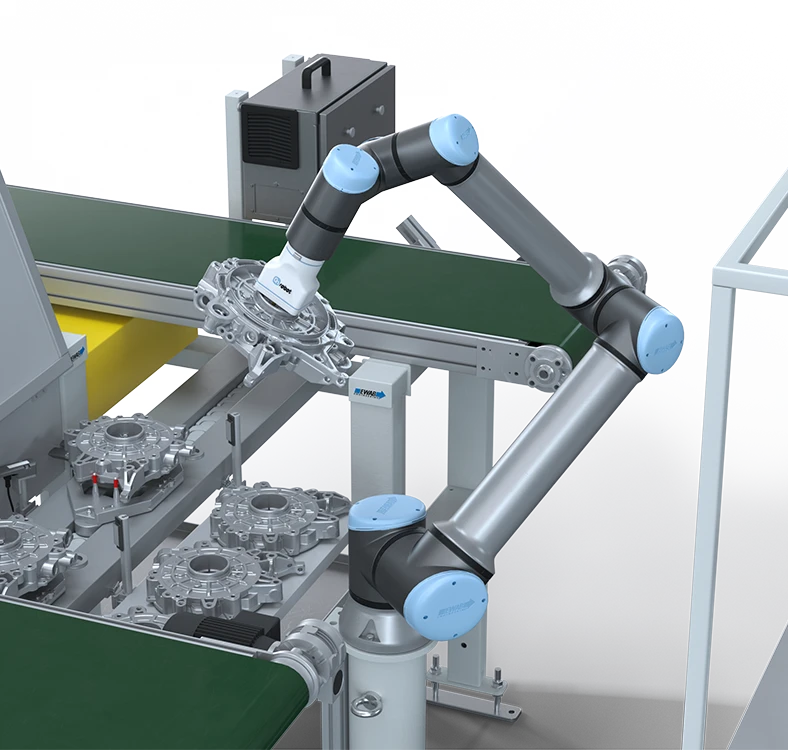

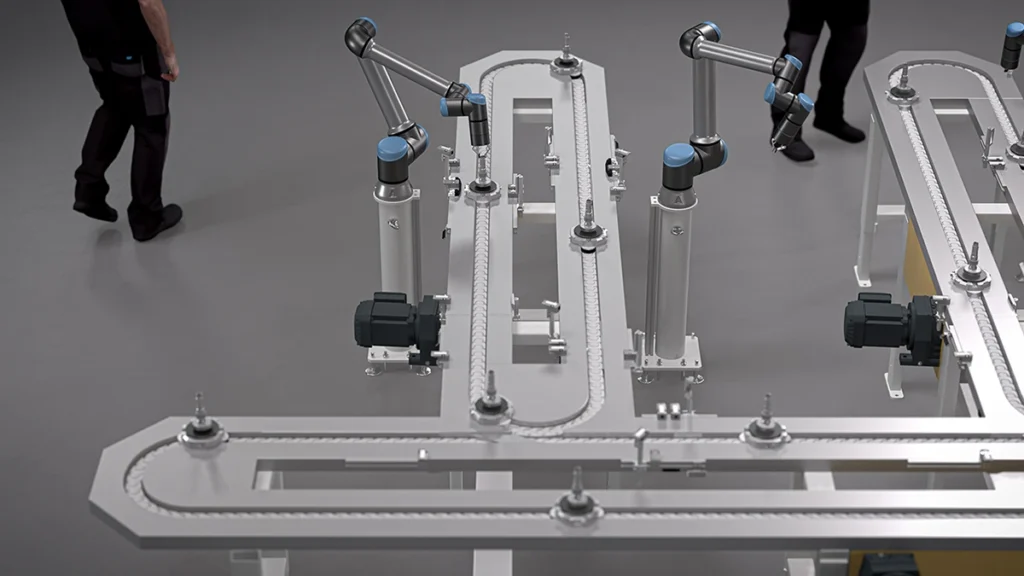

Cobots integration can be done in many ways and works well for loading & unloading parts on the conveyor system. A cobot can also be used for quality control and repetitive tasks in an assembly line, where humans and cobot works side by side.

At EWAB, we have experience from many different projects and the conveyor lines have standardized interfaces to cobots and robots. Explore the versatility of a collaborative robot for efficient part handling, assembly line automation, and seamless integration with EWAB line.

Cobots in Manufacturing

– Loading & unloading the conveyor

– Workpiece handling

– Quality control

– Palletizing

Cobots in Assembly lines

– Cobots for repetitive tasks

– Loading/Unloading

– Cobots & humans working side by side

Cobots in Manufacturing

A collaborative robot can be a great complement for a 6-axis robot in a production line. Cobots enhance manufacturing by automating key tasks: they efficiently load & unload conveyors, handle workpieces with precision, ensure quality control through advanced inspection, and streamline palletizing for faster, safer operations. At EWAB we mostly use the cobot for loading/unloading the inspection operation or the EWAB system solution.

Cobots in Assembly

Cobots optimize assembly by handling repetitive tasks with precision, automating loading/unloading, and safely working alongside humans. They boost efficiency, reduce strain on workers, and enhance productivity, making manufacturing more flexible and collaborative.

Case study – A clean Cobot solution

Read a case study on how we helped customer using Cobots for loading/unloading function in a washing operation.

Experience from projects with ABB Collaborative robots, Fanuc CRX, KUKA cobots and Universal Robots. .