Laser marking station

Mark your parts!

At EWAB, we have extensive experience in laser marking, labelling and verification in automation projects.

We work with advanced labelling systems for accurate identification and tracking.

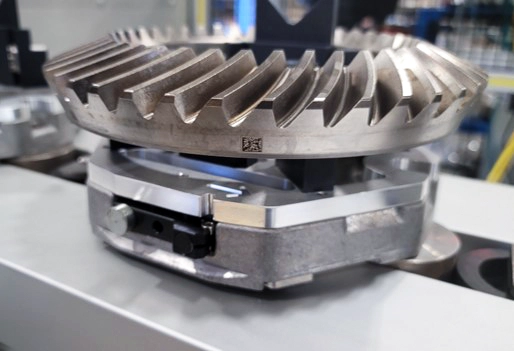

Industrial laser marking stations provide precise, permanent marking for traceability and branding. They efficiently engrave Data matrix codes, serial numbers, and logos on various materials. With high-speed, non-contact technology, they ensure durability and accuracy, making them ideal for automation and quality control in manufacturing

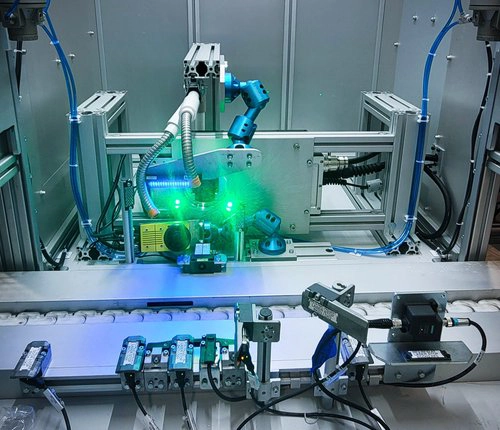

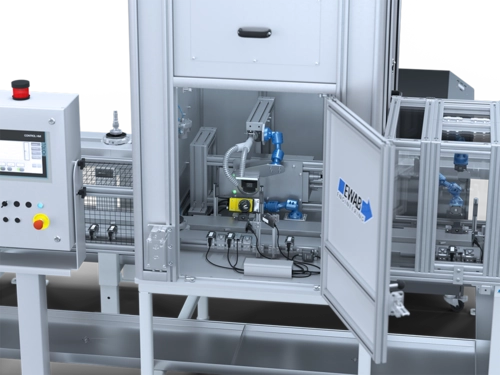

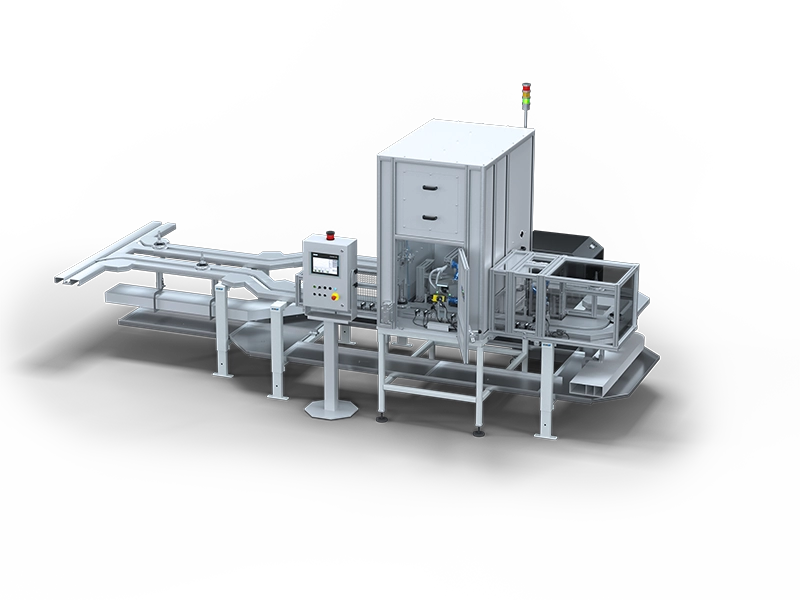

Laser marking station

This station integrates seamlessly with an EWAB pallet conveyor system, ensuring precise and efficient part marking within an automated production flow.

The conveyor delivers each workpiece to the marking station with accuracy, enabling high-speed, consistent, and traceable engraving without interrupting the workflow.

Experience on working with OEM´s and large Tier 1&2 suppliers.

The marking operation suits well straight on the conveyor track.