Quality control station

Control your parts!

In modern manufacturing, quality control is essential to ensure consistent product standards and minimize defects. Integrating a conveyor system with Statistical Process Control (SPC) creates an efficient, automated approach to monitoring and maintaining quality throughout production.

Combining a conveyor system with SPC control allows manufacturers to achieve higher efficiency, reduced waste, and improved product consistency. This proactive approach minimizes rework and downtime, ensuring a cost-effective and reliable production process.

Quality control station

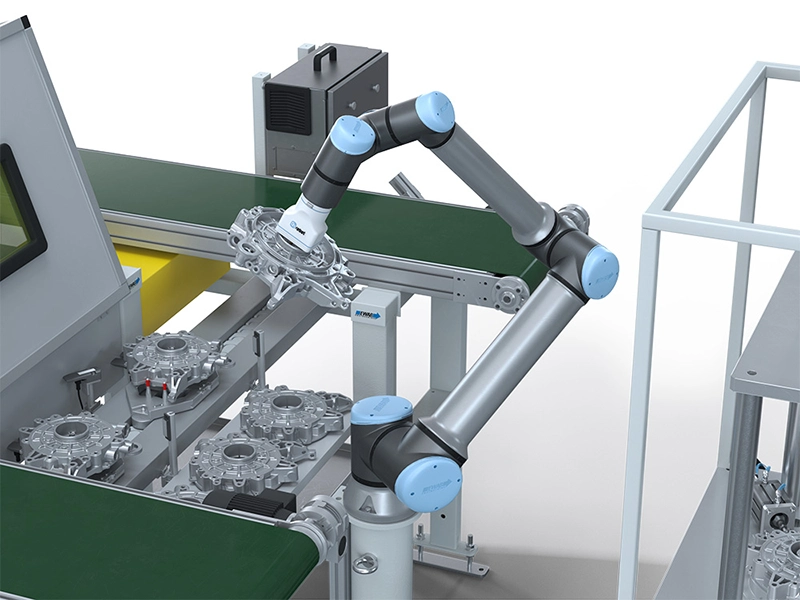

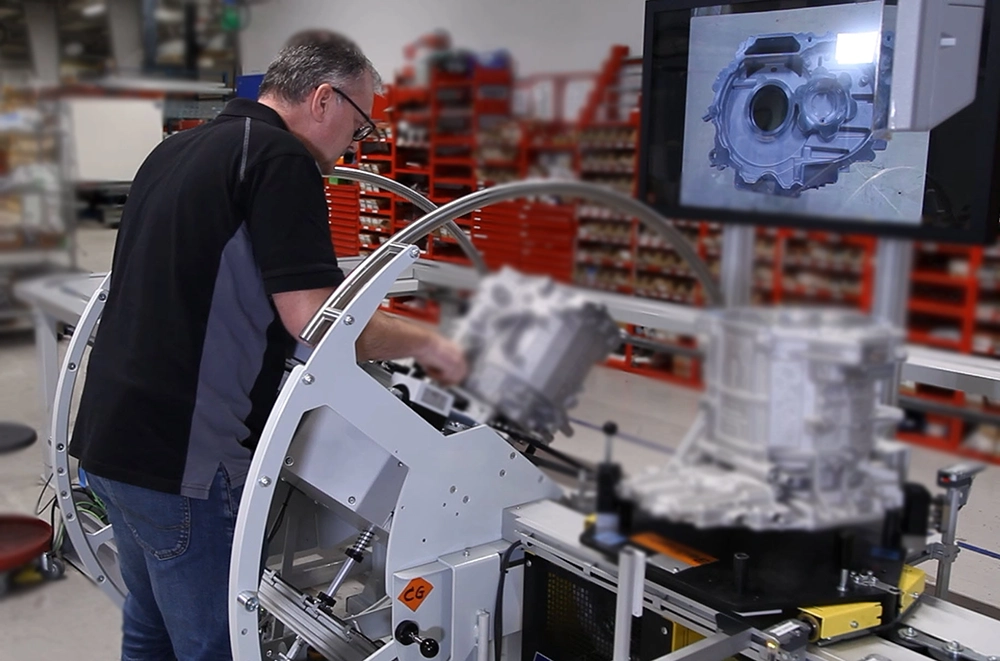

A quality control station can take many forms, from manual inspection points to fully automated systems with vision cameras, sensors, and measurement tools.

It can be seamlessly integrated into the pallet conveyor line for continuous inspection after machining. With vision control and a reject system, it ensures defective parts are identified and removed without disrupting production flow.

Designed to fit specific production needs, these stations ensure precision, consistency, and reliability in manufacturing.

Inspection of parts

For different kinds of SPC control there is different methods for inspection.

- Automated vision inspection for machined parts.

- AI-powered vision inspection for advanced defect detection.

- Manual inspection for detailed quality checks.

- Measurement room inspection for precise analysis and validation.

At EWAB, we offer various solutions that maintain a smooth production flow while minimizing disruptions and optimizing part throughput.

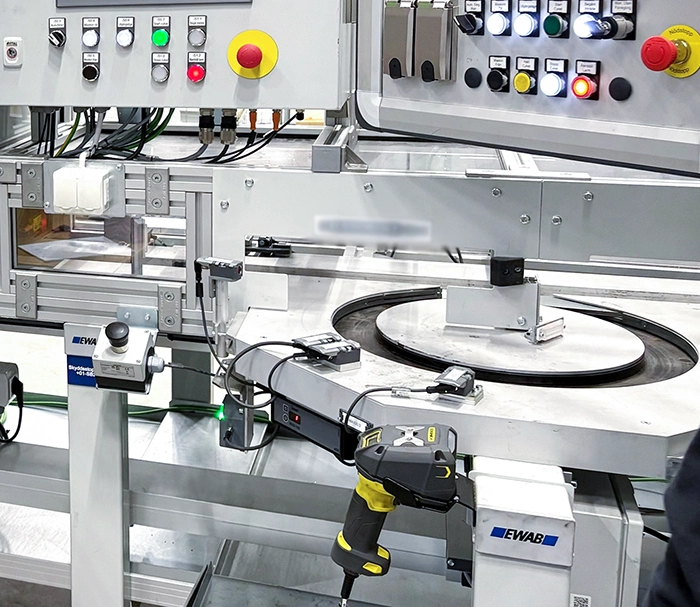

A vision system integrated into the conveyor track is commonly used to control and verify the laser marking process.

Integrating quality control, SPC and conveyors in manufacturing

Our experience working with OEMs and major Tier 1 & 2 suppliers has shown that SPC operations integrate seamlessly directly on the conveyor track. Here are some more key factors to consider.

1️⃣ Real-time data collection & monitoring

SPC relies on real-time data from sensors, vision systems, and measurement tools along the conveyor. This data helps detect deviations early, reducing defects and improving process stability.

2️⃣ Automated inspection & reject handling

Quality control stations can use vision systems and laser sensors to inspect products. Integrating an automated reject system on the conveyor ensures that faulty items are removed immediately, preventing them from moving further in production.

3️⃣ Integration with MES & ERP systems

SPC and quality control data can be linked to Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) for improved traceability, reporting, and decision-making.

4️⃣ Minimizing downtime & bottlenecks

Placing inspection points strategically on the conveyor prevents bottlenecks. A well-designed system keeps production running smoothly without unnecessary stops.

5️⃣ Flexibility for different products

Quality control stations must be adaptable to different workpiece sizes, materials, and inspection criteria, especially in mixed production environments.

6️⃣ Compliance & traceability

Industries like automotive, aerospace, and medical require strict quality standards. SPC and conveyor-based inspection help meet ISO, and regulatory requirements by ensuring consistent quality and full traceability.