EWAB workpiece carriers

What is the size, shape and weight?

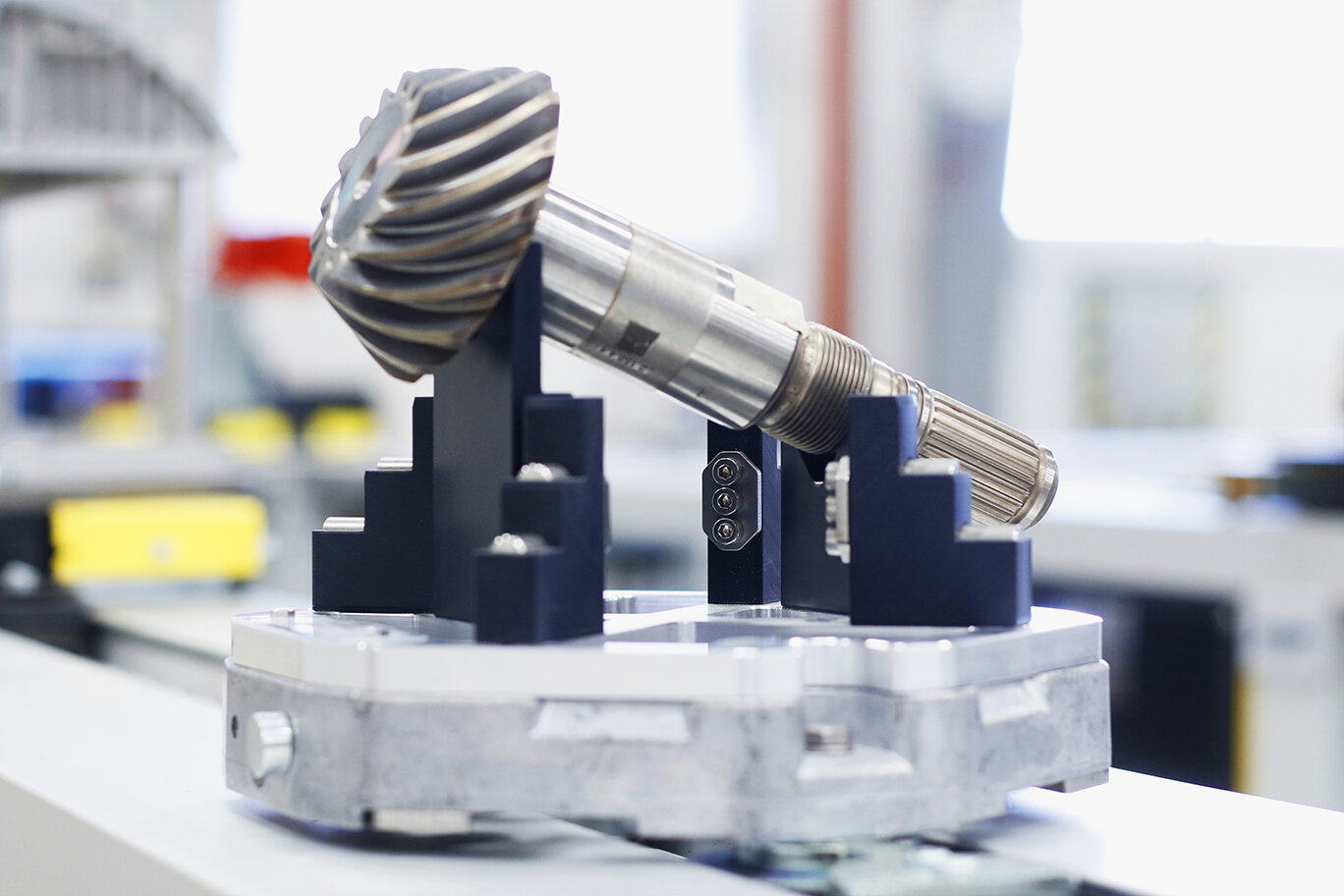

When designing your carrier (pallet) and fixture, several key factors must be considered to ensure a smooth and efficient production flow. The size, shape, and weight of the workpiece are the primary characteristics that determine the optimal design.

Since the workpieces will move through multiple operations, they must be securely positioned on a customized fixture that ensures stability, precision, and repeatability. A well-designed carrier not only protects the workpiece but also enhances process efficiency, reduces handling errors, and improves overall production quality.

By tailoring the fixture to your specific needs, you can maximize throughput, minimize downtime, and create a seamless transition between operations.

Size and Weight

In the end, the size, shape and weight of the workpiece is mostly important from an ergonomically point of view.

If there are manual operations taken place they need to be conducted in a safe and ergonomic manner, without impacting the performance of the flow and throughput of parts.